ELECTROPNEUMATICS AND HYDRAULICS (I) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELECTROPNEUMATICS AND HYDRAULICS (I) P.LTD.

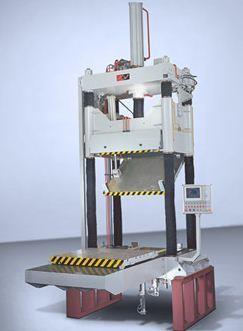

Hydraulic Moulding Presses

Composite materials are substituting steel and aluminium for manufacturing automotive structural parts and skin panels with first-class surface quality because they are light-weight and yet structurally strong. Electropneumatics presses for forming and moulding of engineering plastics/composites (such as SMC, DMC, FRP, epoxy, etc.) and also automotive interior fabrics and friction material for brake and clutch facings meets this demand. These machines have features specially designed to control the forming, heating and cooling cycles and accurately level, form and eject parts to achieve Grade I component surfaces.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.